|

New

Release�I�@�@�@�@�@�@�@�@Japanese

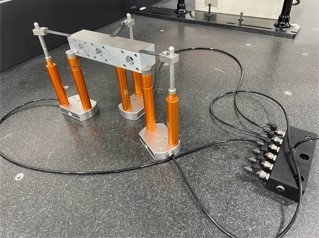

Air-fix

is a "Time Saving Fixture " that increases productivity

by moving a coordinate measuring machine or a work on a stone surface

plate smoothly and fixing it tightly. Air-fix shorten the setup

time! This product offers great advantages when measuring single

items or small lots!

Air-fix�@22B1Movie�iShort

Version�j

Air-fix�@22B1Movie�iLong

Version�j

Air-fix�@22B1Movie�iAttaching

Magnet Stand�j

Air-fix

�@22B1 Movie�iSurface Roghness Measuring Machine usage example)

Air-fix

�@22B1 Movie�iContour Measuring Machine usage example)

It was

jointly developed by Mitutoyo Co., Ltd. and Sasaki Koki Inc. which

received a patent license from Mitutoyo Co., Ltd. (Kawasaki City,

Kanagawa Prefecture), a manufacturer of precision measuring equipment.

Furthermore, a joint patent application has been filed between the

two companies for this product.

[Patent No. 4616563] [Japanese Patent Application No. 2022-042420]

<What

is Air-fix�H>

A vacuum

suction type fixture that can fix the work at any position on a

coordinate measuring machine or stone surface plate. It is firmly

adsorbed on the surface plate just by supplying compressed air.

Adsorption to stone surface plates and ceramic surface plates, which

is not possible with magnet jigs, is possible. Even during suction,

it can be easily moved and attached by simply pressing the exhaust

port with your fingers.

<Use>

�@ Instead

of Eco-fix baseplate (no need for baseplate)

�A For positioning and abutting of workpieces

�B Can be used for workpiece fixation using clamping tools

�C For the dial gauge stand

�D For holding a large work that protrudes from the Eco-fix base

plate

�E For the base of the magnet stand

��Eco-fix

is a clamping tool of Mitutoyo

Co., Ltd. By combining each element like a block toys, it is a clamping

system that can easily fix various measurement objects

�@

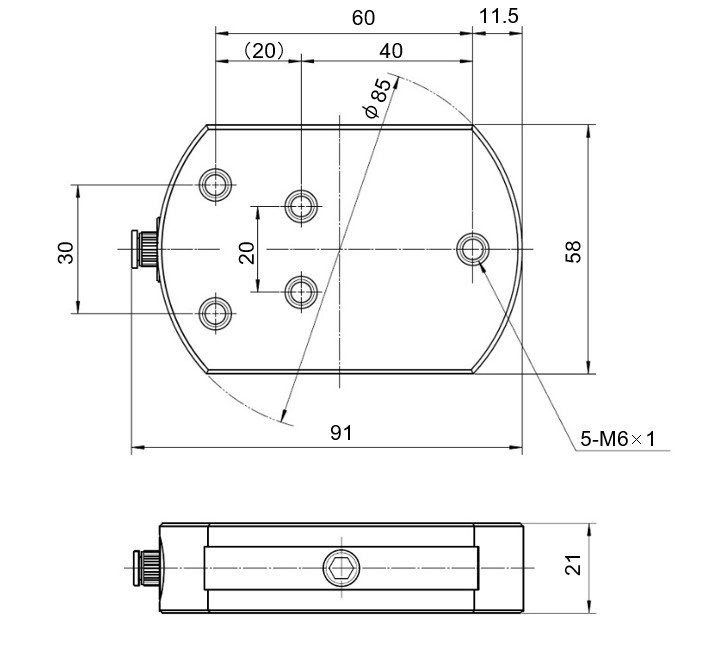

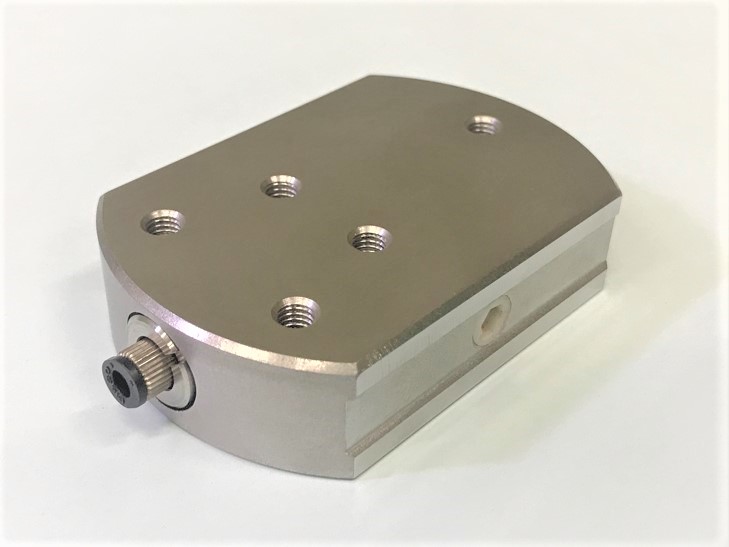

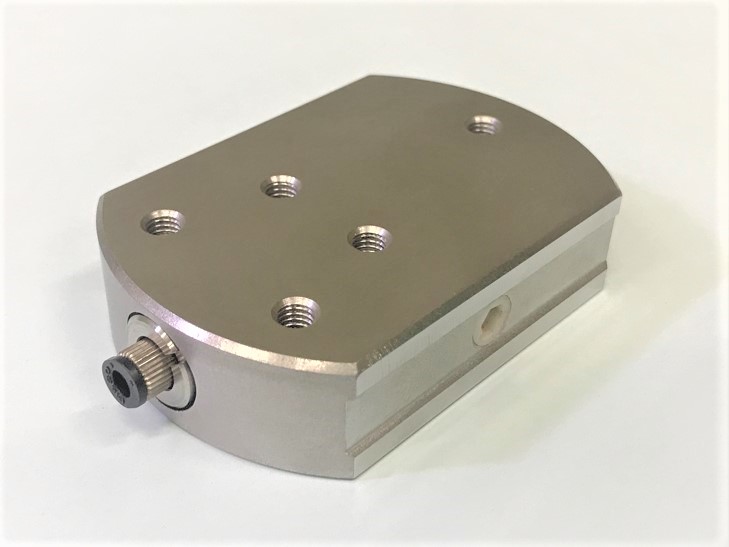

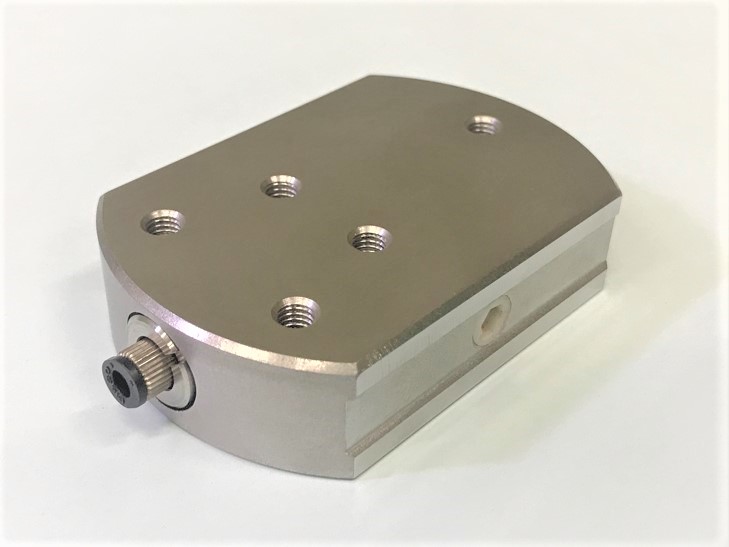

<Specifications>

Size

�F21 mm x 58 mm x 91 mm, weight 630 g

Air Consumption

Flow Rate �F8 L / min <in standard condition>

Adsorption

Retention�F200 N (20.4 kgf) <vertical direction> 65 N (6.6

kgf) (spring plate tip)

Quietness (Operating

Sound) �F50dB The standard of operating sound is 50dB, which is about

a quiet office.

Loading Weight

:Max 10kg for ��12mm location pin up to 50mm length, max 1kg for

over 50mm up to 100mm

�@The

table below summarizes the load on the Air-fix location pin for

Mitutoyo CMMs.

�@�@�@�@�@�@�@�@ �@When using

��12 location pin

�@�@�@�@�@�@�@�@�@�@�@

�@

�@�@�@�@�@�@�@�@�@�@�@�AWhen

using ��20 location pin

�@�@�@�@�@�@�@�@�@�@�@

*

A 3-Port Manifold, 6-Port Manifold, and Piping Set are available

as optional items. Please contact us for details.

* Air supply

equivalent to 0.4MPa is required.

* Warranty

:1 year from purchase

<Air-fix

22B1 Instruction Manual >�@�@�@�@�@�@Download

PDF here.

�@

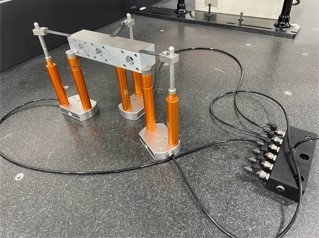

��Commodity composition��

(1)�@Air-fix�@Body�i1�@Unit�j

�@

�@

Optional

item

(2)�@6-Port Manifold�@ �@�@�@(3)�@3-Port Manifold�@�@�@(4)�@Piping set

�@�@�@ �@�@�@ �@

�@ �@ �@

�@ �@

�@

Piping

set configuration

*Piping set configuration

��4 tube, ��6 tube, hand valve, reducer, tube fitting, coupler (total

length about 3 m)

* Mitutoyo standard products are recommended for spring clips and

screw adapters.

(5)�@Clamping Tool Extension Set-A

��12 Location

Pin L100�~6pcs

��12 Location

Pin L 50�~6pcs

��12 Location

Pin L 25�~6pcs

Straight Pin�~3pcs

Spring Clip�~3pcs

<Adsorption

principle>

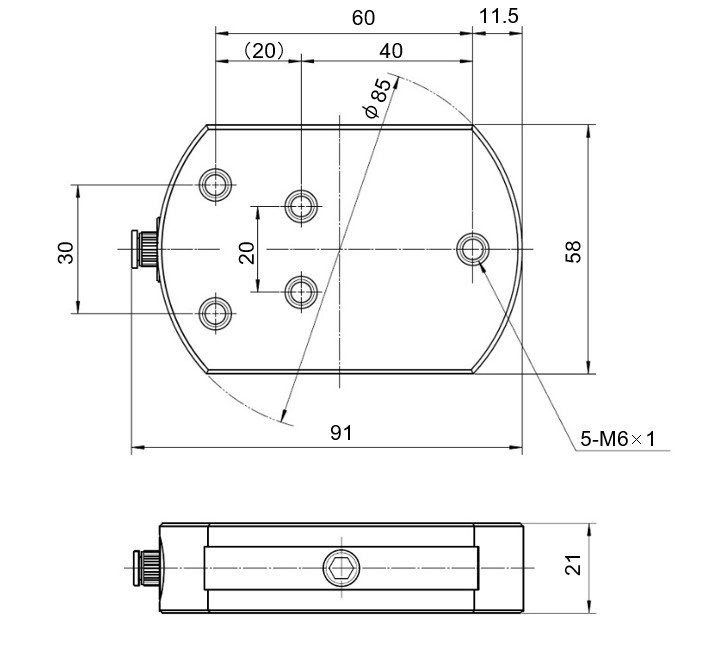

<Dimensional

Drawing>

�@

�@

�yPositioning of workpiece�zIf

you decide the position to hit in advance and set it, you can improve

the efficiency of inspection of mass-produced products just by exchanging

the workpiece.

|

�yFixing

a work with a flat surface�zEasily fix and position workpieces

with a flat bottom.

|

�yFixing

workpieces with few surfaces to hold�zThere is no problem

even if there is only a place to fix the end face of the

work.

|

|

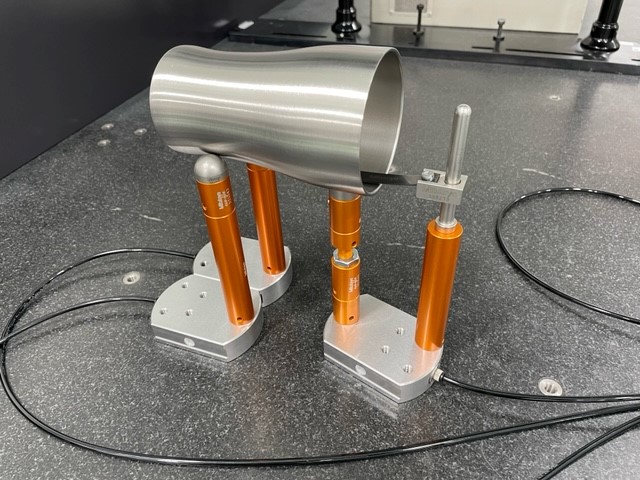

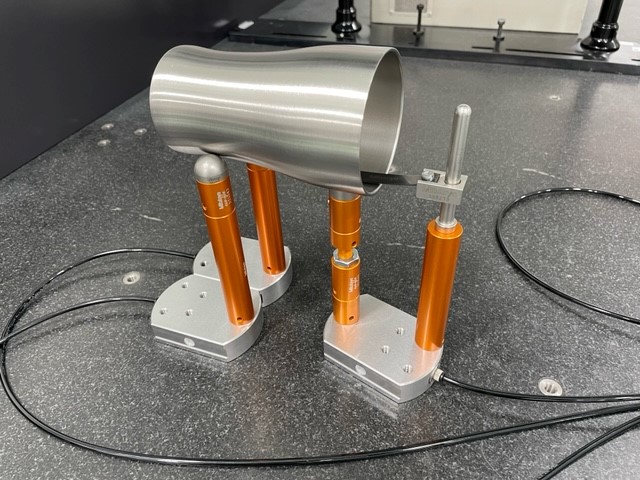

�yFixing large

workpieces�zWorkpieces

that do not rest on the Eco-fix base plate can also be easily

fixed using spring clips. It is also effective for reverse

engineering.

|

�yFixing

a workpiece with a curved surface�zEasily fix workpieces

with curved surfaces that are difficult to position.

|

|

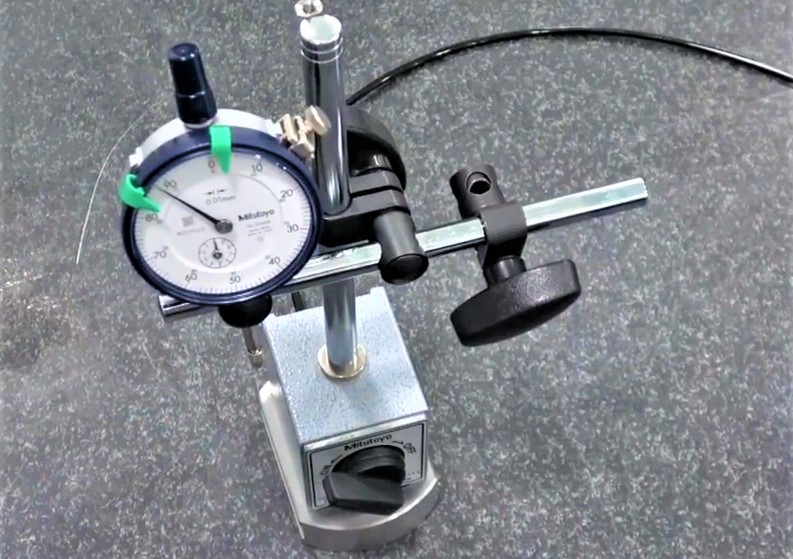

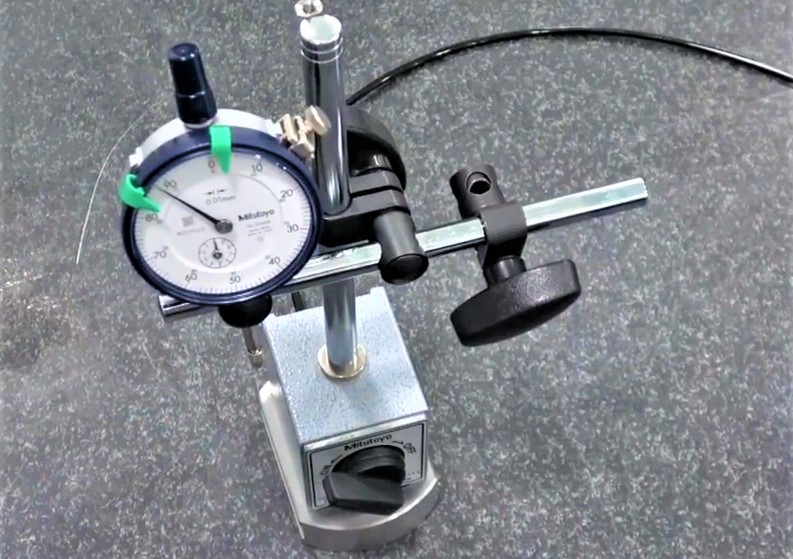

�yFixing

measuring instruments�zQuickly

fix the dial gauge, etc. that you want to fix to the stone

surface plate together with the magnet stand

|

�yFixing

large workpieces�zWorkpieces that do not rest on the Eco-fix

base plate can be easily fixed using spring clips.

|

��F.A.Q.Frequently

Asked Questions��

Q1. How many millimeters

are the screw holes that stand up the columns on the top of the

Air-fix body?

A1. It is a coarse screw of M6 x P1.0. An optional (paid) conversion

adapter to M8 screws is also available.

�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@

Q2. How can a vacuum

be created with the compressed air of an air compressor?

A2. The Air-fix 22B1 main unit has a built-in small vacuum generator

called an ejector. Air is supplied from the ejector supply port

and air is discharged from the exhaust port to create an air flow.

Air-fix 22B1 There is a groove in the air reservoir at the bottom

of the main body, and the air in it is put on the air flow created

by the ejector and discharged to create a vacuum.

�@

Common precautions

for vacuum system equipment

Please be sure to read before using Air-fix.

Please be sure

to read before using Air-fix.

Warning

|

1

|

If

the adsorbent (workpiece) falls and is considered dangerous,

take safety measures by taking fall prevention measures. |

|

2

|

Do not use the vacuum circuit side where pressure of 0.1Mpa

or more is constantly applied. Vacuum equipment does not have

an explosion-proof structure, so there is a risk of damage to

the main unit. |

|

3

|

Please

be careful about the decrease in vacuum pressure due to troubles

in the supply air and supply power supply. Take safety measures

as there is a risk that the adsorbed material will fall due

to the decrease in adsorption power. |

|

4

|

When

two or more pads are connected to one ejector in a vacuum circuit,

if one pad causes adsorption failure (leakage), there is a risk

that the other pads will come off due to a drop in vacuum pressure. |

|

5

|

Do

not use it to block the exhaust port of the ejector or increase

the exhaust resistance. It may not generate a vacuum or cause

a decrease in vacuum pressure. |

|

6

|

Do

not use in an atmosphere of corrosive gas, flammable gas, explosive

gas, chemicals, seawater, water vapor or where it adheres. Also,

never inhale. |

|

7

|

Please

attach a protective cover in places exposed to sunlight. |

|

8

|

Perform

regular maintenance and inspection of the silencer element of

the ejector and the filter element of the vacuum filter. Clogged

elements may cause performance degradation or trouble. |

|

9

|

When

replacing the element, make sure you understand the vacuum ejector

replacement element well. |

|

10

|

Check

each port of the ejector by checking the text and the display

on the main body, and perform piping. Incorrect piping may cause

damage to the main unit. |

|

11

|

For

the ejector supply air, remove drains and dust and use clean

air. Also, do not refuel with a lubricator. Impurities and oil

contained in compressed air may cause malfunction and performance

deterioration. |

|

12

|

Do not give strong tensile force or extreme bending to the lead

wire. It may cause disconnection. |

|

13

|

If

the product has a locknut, be sure to tighten it by hand without

using a tool. If tightened with a tool, it may cause damage

to the locknut or the main body. Also, if it cannot be tightened

securely, the locknut may loosen and the initial setting may

be incorrect. |

|

14

|

Do

not forcibly swing or rotate the product whose resin body rotates.

It may cause damage or leakage of the main body. |

�@Inquiry�@Sasaki

Koki .Inc.

TOP

|

�@�@�@

�@�@�@ �@

�@ �@

�@

�@ �@